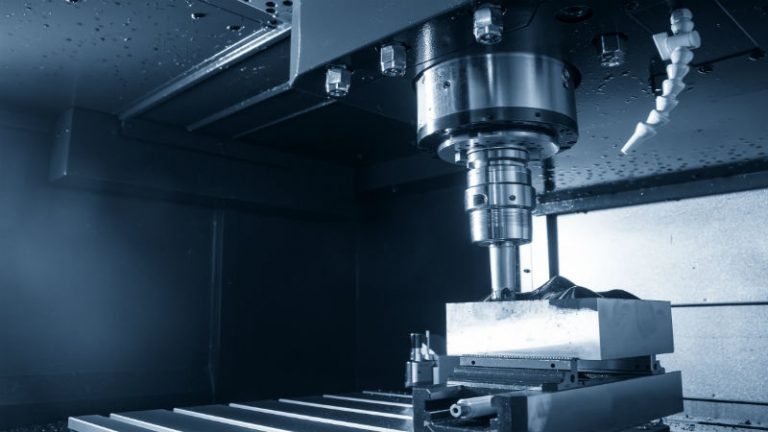

The construction industry constantly evolves, with new technologies and materials driving project efficiency and longevity improvements. One such advancement significantly impacts the adoption of advanced manufacturing techniques that reinforce structures and components. Increasingly, builders and architects are searching for innovative solutions to enhance durability, and Sheet Metal Forming has emerged as a leading method for achieving these goals. This process is highly sought for its ability to shape metal into precise forms, ensuring strength and versatility in modern construction projects.

Enhanced Durability Through Precision Engineering

One of the primary reasons construction professionals turn to sheet metal forming is the remarkable durability it imparts to building components. By manipulating metals such as steel and aluminum into customized shapes, engineers can create parts that are strong and resistant to corrosion and wear. This precision ensures that metal components fit seamlessly into architectural frameworks, reducing the risk of structural weaknesses and extending the lifespan of buildings.

Versatility in Modern Construction

Sheet metal forming is not limited to a single application; it is used in everything from roofing and façade elements to HVAC systems and structural supports. Its adaptability allows architects and designers to experiment with complex geometries without sacrificing strength or reliability. This flexibility is especially valuable for projects that demand unique aesthetics or must meet stringent performance requirements. Fabricating intricate shapes with consistent quality helps streamline installation processes and minimizes on-site modifications, saving time and resources.

Driving Sustainable Building Practices

Beyond durability and versatility, sheet metal forming contributes to sustainability in construction. The process generates minimal waste, as materials are precisely cut and formed to specifications. Additionally, many metals used in this method are recyclable, supporting green building initiatives and reducing the environmental impact of large-scale projects. As sustainability becomes a higher priority in the industry, the demand for efficient, eco-friendly manufacturing techniques continues to grow.

For construction professionals seeking robust, adaptable, and sustainable solutions, contacting Staub Manufacturing Solutions is a strategic step forward. As a trusted Sheet Metal Fabricator, they are ready to assist with your next project—reach out to them today to learn more.